ECO Plant

Smart Logistics Solutions

Hyundai Rotem provides smart logistics solutions for all industries and service sites such as logistics automation systems, automotive conveyor system, AGVs for transporting containers in ports, boarding bridges, cargo handling systems in airports, etc., including logistics warehouses, car factories, ports, and airports.

Logistics Automation System

Hyundai Rotem has been developing and supplying core logistics automation equipment such as AGVs (automated guided vehicles), AMRs (autonomous mobile robots), automated warehouses, automated unloading equipment, etc. As well as proposing optimal solutions to satisfy customer requirements through consulting and providing integrated smart factory solutions covering the whole process of design, manufacture, installation of customized equipment, and predictive maintenance service for stable operation.

AGV

AGV

Automated warehouse

Automated warehouse

Automotive Conveyor System

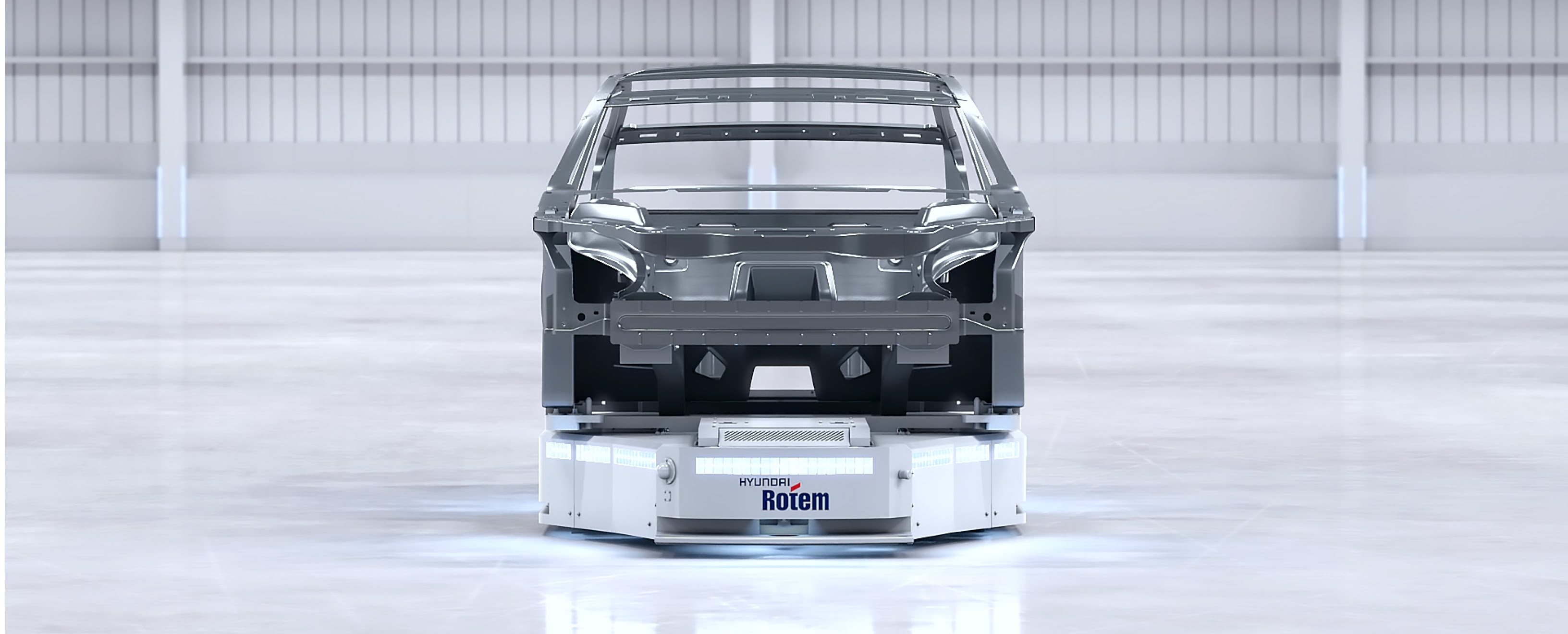

Hyundai Rotem has been supplying major conveyor system for automobiles and parts to Hyundai Motor Group companies at home and abroad, Hyundai Motor Company, Kia, and Hyundai Mobis. Moreover Hyundai Rotem has secured world-class technology and quality through a number of delivery records, provides various types of equipment, including skillet, skid, and friction systems, EMSs (electrified monorail systems), automated warehouses, AGVs (automatic guided vehicles), AMRs (autonomous mobile robots), etc., as well as engineering services for domestic and foreign internal combustion engine and electric vehicle customers.

Skillet system

Friction system

EMS system

AGV

Port AGV System

Hyundai Rotem provides a total solution for container transportation at ports and is engaged in the supply and maintenance business for the related systems and infrastructure necessary for the operation of control programs, automatic chargers and AGVs in ports, including AGVs capable of transporting heavy loads of 65 tons or more. Hyundai Rotem has the basic technology necessary for port AGVs, such as vehicle body manufacturing technology for trailer drones (a next-generation cargo transport platform), autonomous driving technology for field tactical vehicles (HR-Sherpa), electrification technology for high-speed train and hydrogen fuel cell trams, and design/manufacture/control technology for smart factory process transport AGVs, etc. Hyundai Rotem is contributing to the localization of automatic transport equipment in ports and the improvement of port logistics competitiveness in line with the government's domestic port automation industry fostering policy.

Boarding Bridge∙Baggage Handling System

Hyundai Rotem is stably engaged in equipment supply, engineering, and maintenance businesses optimized for domestic and international airport/port environments based on 26 years of accumulated technology and in line with customer requirements and the rapidly changing demands of the airport/port market. Representative facilities include fixed link bridges and passenger boarding bridges for aircraft/cruise passengers. In addition, there is a baggage handling system for receiving, searching, storing, and transferring passenger baggage from the departure airport to the aircraft, and transferring checked baggage to passengers at the baggage claim area of the destination airport. There is also an airport logistics automation system for the unmanned reception, search, and barcoding of air cargo stored in cargo terminals, transportation/storage of the cargo in an automated warehouse through an autonomous mobile robots, and unmanned transporting the cargos to the ULD (unit load device) packing zone according to the flight schedule.

Airport boarding bridge

Port boarding bridge

Baggage handling system

Baggage handling system